APPLICATIONS

Cool Star® compact chillers have a wide range of applications, particularly in commercial and industrial refrigeration. They are used in food production, chemical and mechanical manufacturing, for food refrigeration and freezing, in plastics production and metal machining, in air conditioning and ventilation systems, for cooling of ice surfaces and data centres, and for cooling of process fluids and liquid products.

Cooling capacity | 20 kW – 1,5 MW |

Outlet temperature of liquid | –40 to +30 °C |

Ambient temperature | –25 to +45 °C |

NATURAL REFRIGERANT

Ammonia (NH3) is a naturally occurring substance, with no negative environmental effects and zero ODP and GWP, so it cannot damage the Earth’s ozone layer and has no effect on global warming.

Ammonia is a traditional refrigerant that has been in use for over 180 years. Its properties are well known, and no negative environmental effects have ever been found. This refrigerant is readily available worldwide and its price is stable over the long term.

Combining the unique properties of ammonia and modern technology of Cool Star® chillers means a truly natural and long-term path in the field of refrigeration.

EFFICIENT AND ECONOMICAL OPERATION

Ammonia (NH3) provides very high volumetric cooling capacity, among the highest of conventional refrigerants. This leads to a significantly lower need for refrigerant transport per unit of cooling capacity, resulting in significantly lower energy consumption. Operational efficiency can be further increased by incorporating heat recovery systems, or by combining with free cooling, etc.

Compared to systems using synthetic refrigerants, an investment in Cool Star® chillers is recovered through energy savings over a period of 3 to 5 years, with a significant saving for each additional year of operation.

With proper maintenance, the lifetime of Cool Star® chillers may be measured in decades and savings can be really impressive.

ULTRA LOW REFRIGERANT CHARGE

Cool Star® compact chillers excel thanks to the physical properties of the NH3 refrigerant and the unique design using an extremely low refrigerant charge of units of kilograms up to tens of kilograms depending on the chiller size.

This exceptionally low refrigerant charge makes Cool Star® chillers extremely safe.

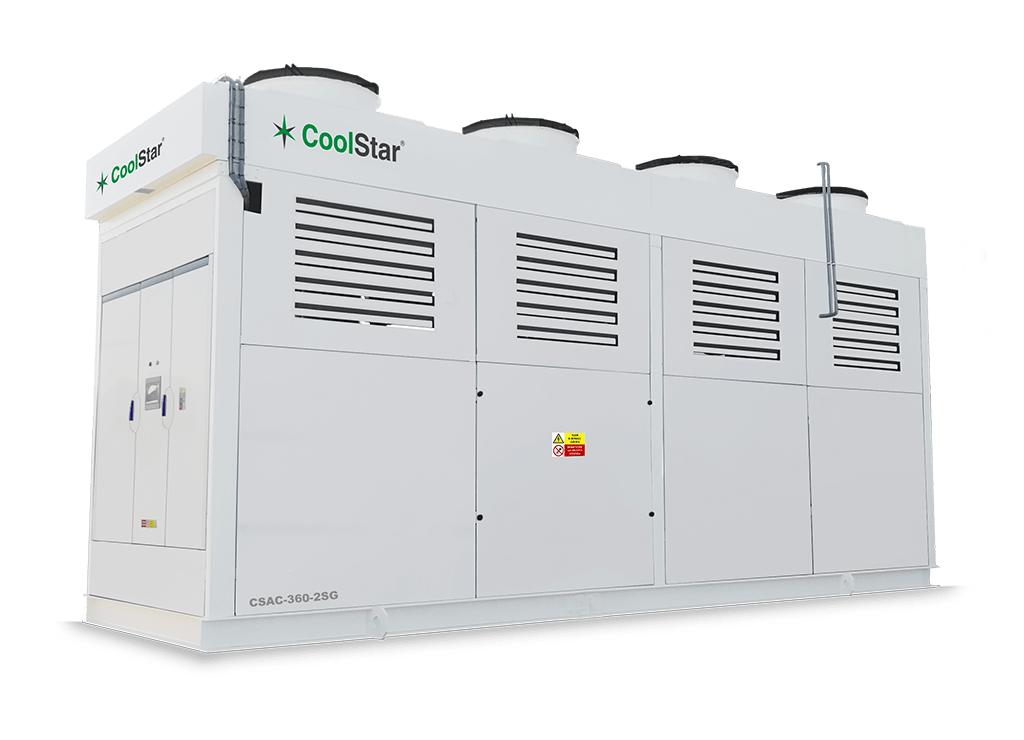

DESIGN

Cool Star® chillers have a unique and compact design. They are designed for high reliability, safety, long life, minimum space requirements and simple installation. The system works on the principle of a flooded evaporator to ensure the best operational and energy efficiency.

These chillers are designed for fully automatic operation and can be equipped with a remote control and monitoring system at the customer’s request.

EASY INSTALLATION

Cool Star® compact chillers are ready for “Plug & Play” installation. They are quick and easy to install and start up, with no complicated assembly or interconnection of individual system parts at the customer‘s side.

Cool Star® chillers can be located both outside and inside the buildings. If an outdoor design is chosen, there is no need for the customer to build a machine room.